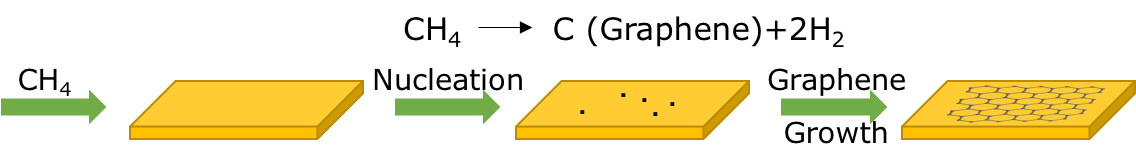

Graphene grown on copper by chemical vapor deposition cvd has been significantly explored for the synthesis of high quality graphene since the popular recipe for single layer graphene growth was introduced in 2009 1 many years after the first report of the deposition of graphene on cu in 1992 2.

Cvd graphene copper etching.

In addition we found that the etching is temperature dependent.

After the copper was etched the pmma pva graphene block was rinsed with deionized water three times at 0 c and transferred onto a 100 nm thick sio 2 si substrate.

For the fecl 3 etchant we found that the average size of the.

Advanced materials 2016 28 29 6247 6252.

Here to investigate the size and density of the graphene domains the cvd growth of graphene was terminated by stopping the ch 4 feedstock prior to covering the entire cu surface.

If the raman spectra of bilayer graphene transferred to pet wafer is compared to that the one of bilayer graphene on copper figure 2 a it can be concluded that the different transfer steps affected the.

We report a simple clean and highly anisotropic hydrogen etching method for chemical vapor deposited cvd graphene catalyzed by the copper substrate.

Wei guo feng jing jian xiao ce zhou yuanwei lin shuai wang.

2a and b show the etching time evolution of the graphene domain size on the copper foils etched by an fecl 3 or an nh 4 2 s 2 o 8 etchant.

Figure 4 shows the raman spectra of the cvd grown bilayer graphene transferred onto pet wafers using the three different etching solutions.